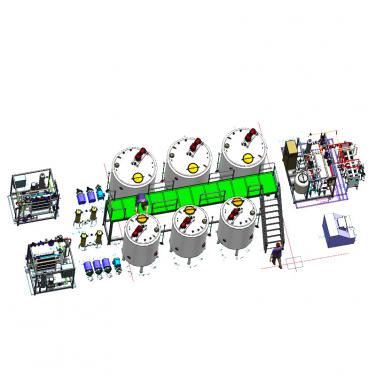

Warning signs will appear on the screen during the daily work of falling film evaporator. We can judge the working condition of the equipment according to different types of warning signs. So as to take effective measures to operate the equipment correctly, so as to make the working environment of workers more safe.

During the operation of falling film evaporator, the surface temperature of some equipment can reach about 100 ℃. If you touch these high-temperature surfaces without any protective devices, it will cause serious burns. Therefore, anti scald warning signs shall be pasted at eye-catching positions on the surface of high-temperature equipment.

2. Falling film evaporator chemicals

The cleaning process of falling film evaporator is applied to a variety of reagents. These reagents can be used only after they are diluted according to the required concentration. People handling these reagents need special care and they must wear appropriate protective equipment.

It is strictly forbidden for operators to open or repair electrical equipment. Only full-time electricians can inspect or repair electrical equipment. The electrical cabinet door must be locked, and only authorized electricians can open the electrical control cabinet.

Before starting the falling film evaporator, it must be ensured that the equipment manhole has been closed, all pipelines have been reconnected, and all potential safety hazards with leakage have been eliminated.

5. Equipment maintenance of falling film evaporator

In order to ensure the long-term trouble free operation of falling film evaporator equipment, the evaporator equipment shall be systematically overhauled and maintained in time after the end of each pressing season.

Warning Sign

a. Turn off the power and lock the control cabinet door.

b. Make and post warning signs to prevent restart.

c. The supply pipelines of steam, compressed gas, CIP, etc. of the concentration evaporator equipment shall be closed.

d. Mechanical lifting device must be used for overhaul and maintenance of large components.

e. The tightness of all connecting bolts must be ensured.

f. After all maintenance work is completed, check the function of the safety device.