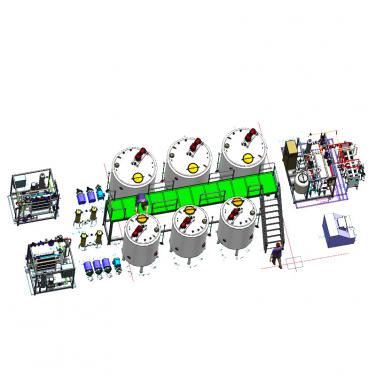

Configuration of various components of concentration evaporator and introduction to technical terms

Jun 13, 2022

Concentration evaporators are widely used in fruit processing lines and biopharmaceutical processing lines. There are many professional terms related to concentration evaporators. Today, let's talk about the meaning of the main professional terms of concentration evaporators.

Evaporator

The object in the tube is heated, and the material is boiled and vaporized.

Separator

The separation of steam and liquid is carried out in the separator, and the evaporated secondary steam is used as the heat source of the next effect. The liquid is pumped to the next efficiency through the material pump.

Surface condenser

The final secondary steam of the evaporator is condensed in the surface condenser. In order to avoid mixed pollution, a surface condenser is used, with secondary steam outside the tube and cooling water circulating inside the tube.

Vacuum

The evaporator internal pressure is lower than the external atmospheric pressure. In order to reduce the heating temperature of materials, low-temperature vacuum compression is adopted, and water vaporization is carried out in vacuum.

Concentrate

Concentration refers to the process of reducing the water content in materials by evaporation. Materials are heated to boiling, and all or part of the water changes from liquid to gas.

Preconcentration

This is the material boiling point feed to reduce the heat load of the evaporator.

Safety valve

When the steam pressure exceeds the set pressure, the safety valve opens automatically to protect the equipment.

Material throttling

In order to avoid cavitation of the pump, a throttle regulating ball valve is installed at the pump outlet.

Frequency converter

An instrument that controls the speed of a motor by adjusting its frequency.

Plate heat exchanger

It is mainly used for heat exchange between materials to increase or decrease the temperature of materials.

Sealing water

The soft water supplied to the mechanical seal of the pump takes away the heat generated by the mechanical seal in time to protect the mechanical seal.

Cooling tower

The secondary steam is cooled, and the steam is used to change from steam to liquid.

Vacuum pump

The non condensable gas in the evaporator is extracted and evaporated in vacuum.

Vacuum regulating valve

The valve installed in the vacuum system is used to adjust the vacuum of each effect so as to control the temperature gradient.

Thick juice

It refers to the high concentration product obtained after the low sugar product is removed by evaporation.

Condensate

It refers to the water evaporated from fruit juice and condensed by the wind.

Sub cylinder

It refers to the water vapor transfer buffer cylinder, which is the device for the steam consumption point of the evaporator.

Прошлая страница:

Warning signs for falling film evaporator

Следующая страница:

Advantages of four effect falling film evaporator

Новости

Популярная продукция