Milk is a product that is easy to deteriorate. From the perspective of manufacturers, milk products can be stored for a longer time before they can be delivered to consumers who need it. Milk should be sterilized in the production process, so that milk products have a longer edible value, and milk products can fully meet the market demand of further geographical locations.

From the perspective of ordinary consumers, milk products that are easier to preserve are also very popular, which gives people more time to consume milk products.

High temperature treated milk must be of good quality. In particular, the protein in raw milk will not cause thermal instability. The thermal stability of protein can be quickly determined by alcohol test. When the milk sample is mixed with an equal amount of ethanol solution, the protein may become unstable and the milk will flocculate. The higher the concentration of ethanol solution added without flocculation, the better the thermal stability of milk. If milk remains stable (not precipitated) even after adding an alcohol solution with 75% alcohol concentration, production and shelf life problems can be largely avoided.

Alcohol testing is usually used to reject milk that is not suitable for UHT treatment because it:

It is acid, because the number of acid producing microorganisms is very high.

There is a wrong salt balance

It contains high levels of serum protein, which is a typical feature of colostrum

Raw milk with poor quality has adverse effects on processing performance and final product quality. The reduction of the thermal stability of milk with a pH value lower than 6.65 at 20 ° C will not only lead to processing problems, such as short running time caused by burning on the heating surface, but also lead to difficulties in cleaning and protein precipitation at the bottom of the package during storage.

Milk stored at low temperature for a long time may contain a large number of psychrophilic bacteria, which can produce thermostable enzymes, which are difficult to be completely inactivated by heat treatment. During storage, these enzymes can cause sensory changes, such as rancidity, bitterness, and even gel (aging, thickening, or sweetening).

The bacteriological quality of milk must be high. This applies not only to the total number of bacteria, but more importantly, to the count of spore forming bacteria that affect sterility.

The term "commercial sterility" is often used for UHT treated products. Commercial sterile products refer to products that do not contain microorganisms that grow under major conditions. In low acid products (products with pH higher than 4.5), spores are the most heat-resistant microorganisms that can grow. Because its heat resistance is much higher than that of nutritional microorganisms, the sterilization process only focuses on the killing effect of spores. This group of low acid products includes not only milk, but also most milk based products.

When microorganisms and / or bacterial spores are subjected to heat treatment or any other kind of disinfection / disinfection procedure, not all microorganisms will be killed immediately. Instead, in a given period of time, some parts are destroyed, while the rest survive. If the surviving microorganisms receive the same treatment for the same length of time again, the remaining microorganisms will be killed in the same proportion, and so on. In other words, exposure to fungicides or disinfectants always kills the same proportion of microorganisms.

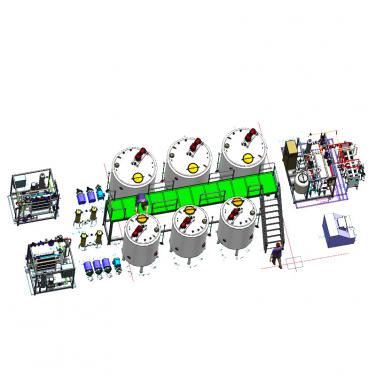

Sterilization efficiency of milk production line

The sterilization efficiency of a milk production line is related to two factors, which are temperature and length of time and the heat resistance of microorganisms.

Other factors such as product composition, viscosity, uniformity, and pH can also affect sterilization efficiency. Flow sterilization equipment - ultra-high temperature (UHT) treatment - typically sterilizes bacterial spores that grow at ambient temperatures around 9-10.

Spores of Bacillus subtilis or Bacillus stearothermophilus are often used as test organisms to determine the sterilization effectiveness of UHT devices, as these strains (especially Bacillus stearothermophilus) form fairly heat-resistant spores. Botox is traditionally used to calculate the effectiveness of in-container sterilization (see F0 value calculation).

The sterilization process must be designed so that there is a negligible risk of the product spoiling or containing viable and growing pathogenic microorganisms prior to use by the consumer. Clostridium botulinum has long been considered the most important microorganism in public health. The sterilization process is designed to destroy the spores of this microorganism. However, the probability of survival and growth of botulinum spores in heat-treated milk and dairy products is indeed low.

The lethal effect on bacterial spores begins at temperatures around 115 °C and increases rapidly with increasing temperature.

Bacteria can be divided into two categories:

those that exist only as vegetative cells (easy to kill by heat or other means),

Those bacteria that exist in a vegetative state and spores, that is, spore-forming bacteria. While these bacteria are easily killed as long as they are in a vegetative state, their spores are difficult to eliminate.

The product to be sterilized usually contains a mixed population of vegetative cells and bacterial spores, as shown in Figure 9.1. Unfortunately, the correlation between the two is not very good. High spore counts may be found in products with low total counts and vice versa, so total count determinations cannot be used as a reliable basis for spore counts in food products.

As mentioned above, the sterilization effect of the heat sterilization process increases rapidly with increasing temperature. Of course, this also applies to chemical reactions that occur after heat treatment. How many times does the reaction rate increase if the system temperature increases by 10°C.

If the process temperature is increased by 10°C, the rate of chemical reactions can be doubled or tripled. The variation is so great because different species of bacterial spores respond differently to increased temperatures. In the UHT temperature range, the bacterial killing effect increases significantly with temperature, while the chemical changes remain mild. This clearly illustrates the advantages of UHT treatment over in-vessel sterilization that operates at low temperatures for long periods of time.

The milk production line integrates a sterilizer, so that it has the ability to sterilize quickly in a cycle, and a large number of milk products can be sterilized during the production process of the processing line. In this way, manufacturers can obtain sterilized milk products that meet market food standards. Milk sterilization technology and sterilization equipment are constantly being updated. More and more advanced sterilization technology will be applied to milk production lines, and more new sterilized milk products. Will also enter the market, these products will greatly meet the different types of needs in the market.