Our UHT milk processing line has made continuous progress in software and hardware. In terms of software program, the new software system will more accurately control each production process. In terms of hardware, the new equipment has been developed, which will replace the relatively backward equipment in the production line with lower cost and higher production efficiency. These innovations will greatly improve the efficiency of the milk production line, especially in UHT milk production.

The new system is particularly suitable for medium-sized UHT milk producers, especially when a new UHT milk production line is installed.

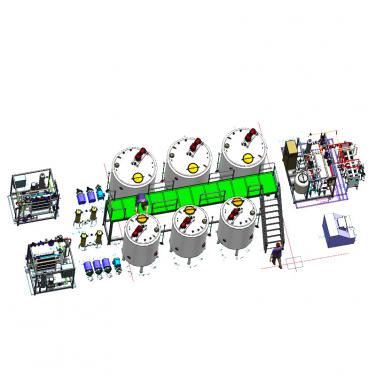

New milk production process

The new technology brings new changes. The raw milk is preheated, clarified, separated, standardized and homogenized in one step. The liquid is then subjected to UHT treatment and regenerative cooling, and then transferred to two sterile buffer tanks. The new system reduces the processing time of the production line from two days to several hours, reducing more than 90% and reducing the operating cost by 50% compared with traditional equipment. The new technology provides customers with a shortcut to UHT milk production. Through the hygienic design of every detail and the comprehensive tracking and control of the production line, the product quality and safety are improved to the greatest extent.

The innovation core of UHT milk is that we combine the heat treatment, separation and standardization stages into a single step, so as to greatly simplify and accelerate the production process. Aseptic buffering is used in the equipment of UHT milk production line. This ensures that the UHT operation is fully automated and continuous, which will result in fewer process steps and less retention in the UHT milk production line. With the accumulation of production time, the production efficiency of UHT milk will be greatly improved.