With the increasing demand for probiotic food in the market, new probiotic processing technologies are also born. These new probiotic processing technologies will change the equipment and process of the current dairy production line, and the efficiency of producing probiotic products will be improved.

The traditional probiotic processing technology achieves its goal by heating. The new probiotic processing technology will not rely on this, which will greatly improve the quality of probiotic food, which gives people more imagination space for new probiotic food.

Promising technology

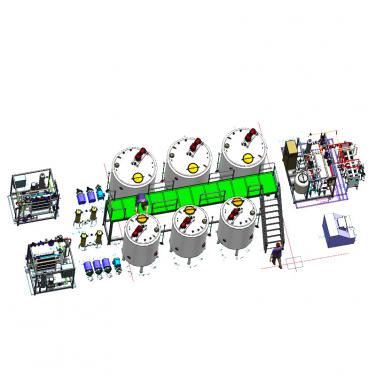

Brazilian scientists have the latest research results in probiotic processing technology. They will soon succeed in developing dairy products with probiotic cultures by using HP and PEF. The application of this new technology to probiotic processing line will greatly improve the efficiency of dairy production line and allow more new probiotic foods to be continuously produced through efficient dairy production line.

In addition to overcoming heat related damage, scientists say these emerging technologies may have a positive impact on some quality parameters. For example, in probiotic yogurt, scientists point out that HP treatment can improve texture and provide stronger and thicker products.

Pulsed electric field technology has great potential in cheese production, because studies have reported the improvement of milk coagulation characteristics, such as gel hardness and coagulation time during cheese production.

The new probiotic processing technology is not perfect at this stage. They will face a problem of high cost investment. The new probiotic processing technology requires new equipment, which is a large investment for manufacturers, which makes many manufacturers carefully analyze and consider before construction.