Plant-based milk is becoming the mainstream in the food field, and more and more people recognize plant-based milk. As a manufacturer, how to grasp this trend and quickly occupy a favorable market position? The simplest way is to quickly own one or more production lines of plant-based milk, so as to greatly enhance their competitiveness in the new field of plant-based milk and successfully achieve the development goal of overtaking in corners.

With our state-of-the-art equipment, we can help optimize your production process, regardless of your capacity requirements or raw materials. With decades of experience in beverage processing, we help you improve the flavor, texture and shelf life of your products while minimizing capital and operating expenses.

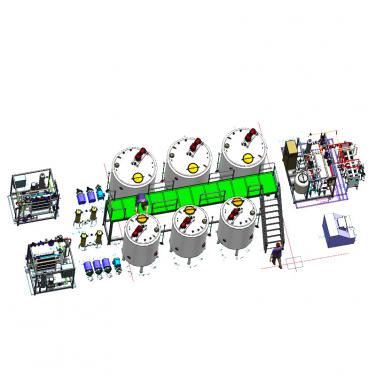

As a start-up in the plant beverage industry, one of the many challenges you face is to develop efficient and reliable production processes. Contact us at an early stage and we will provide you with the know-how and equipment required from conception stage, laboratory and pilot test to commercial production. The R & D and production of all equipment depend on your market objectives and investment scale, so as to maximize the value of your investment. The plant-based milk production line you purchase is what you really need.

Expanding the scale is a learning process. In the process of expanding the scale, it is not uncommon to find products operating in new ways. For example, because the equipment selection is not ideal, many start-ups have experienced inconsistent process results at different stages of development. When this happens, new problems may appear in each new stage, increasing the time to market and development costs.

Another example is that you may experience more products eventually entering the waste stream. We can help you recycle the product and add new value streams from your waste.

Our experts have supported the expansion of many start-ups in the food and beverage industry. They can help you during the design phase and when selecting equipment to ensure a consistent process during the zoom in phase.

Waste is a key problem to be considered in the design of plant beverage production line. It not only changes the production cycle, but also increases the cleaning cost; In addition, it will have a negative impact on the taste and texture of the product.

Customizing heat exchangers to suit process conditions is essential to reduce fouling. If the turbulence is too low and the temperature is too high, the protein and sugar in the plant beverage will cause dirt and may even burn on the surface of the plate.

We have carried out extensive heating and pasteurization in dairy products, beverages and protein applications, and we know how to design heat exchangers to reduce dirt. As there are many kinds of plates with different patterns to choose from, we can provide you with heat exchangers that perfectly match your specific conditions and raw materials.