Ketchup is a product in great demand. It is very popular all over the world. Such products can be produced on a large scale through the ketchup production line. The ketchup production line greatly improves the efficiency from tomato to ketchup, maximizes the processing value of this fruit, and allows tomato, a daily fruit, to be preserved for a long time and become a hot fruit processing product in the market. Ketchup production line includes a series of complex processes such as tomato modeling, tomato peeling and cooking, tomato beating and tomato juice sterilization. The whole process of ketchup processing is realized through a fully automatic production line.

As a professional manufacturer of ketchup production line, we support turnkey projects such as design, manufacturing, installation, commissioning and training of tomato processing plant. Customers only need to tell us the scale of demand and investment, and we can customize the ketchup production line, so as to maximize the use of all resources.

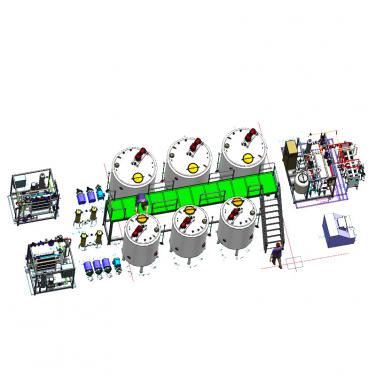

Main equipment of ketchup production line

Tomato bubble washing machineFunction:

It is used for cleaning fresh fruits such as tomatoes, apples, pears and strawberries to ensure the quality of raw materials.

features

▼ the main structure adopts SUS 304 stainless steel

▼ stainless steel nozzle above, high-power water spray

▼ stainless steel roller, designed to prevent tomato patting

Tomato crusher

Function:

This machine is suitable for crushing berries and grapefruit fruits and vegetables. At the same time, it can also crush precooked and softened grapefruit fruits and vegetables with a crushing particle size of 5-8mm.

features:

▼ 304 stainless steel

▼ wide application

Buffer tank

Function:

304 food grade stainless steel temporary buffer 5000L material has any harm to human body.

features:

▼ specifications can be customized according to customer requirements;

▼ made of stainless steel plate, such as sus304/sus316;

Tomato pulping machine

Function:

The utility model is suitable for the separation of tomato residue after crushing and precooking. One is coarse pulping, the other is refined pulp.

features:

▼ automatic separation of fruit juice and residues (peel, seeds, nuts);

▼ different screens can be configured to obtain different processing effects;

▼ it has a wide range of applications

Vacuum continuous evaporator

Function:

It is suitable for vacuum continuous concentration of heat sensitive and high viscosity materials, such as ketchup, at low temperature.

features:

▼ the equipment has the functions of heating, cooling, heat preservation and mixing.

▼ 316L stainless steel is used for the contact part between equipment and materials, and mirror polishing is used for both inside and outside of the equipment.

▼ the tank is equipped with CIP cleaning port, breathing port, material inlet and outlet, observation window, liquid level gauge, thermometer and other components.

Preparation tank

Function:

It is used to mix tomato pulp with other ingredients.

features:

▼ material: #304 stainless steel

▼ 135 ° glass level gauge, 180 ° sampling valve

▼ grind the inner wall with 300 meshes and the outer wall with 300 meshes.

▼ high speed shear head for cutting and mixing products

▼ totally enclosed cover with dust and fly proof vent, 360 ° CIP cleaning nozzle,

▼ digital thermometer, temperature range 0 ℃ - 100 ℃

Ultra high temperature sterilizer

The equipment is widely used in the confirmation and updating of original formulas such as milk, fruit juice, tea beverage, beverage milk, ketchup, condiment, beer, ice cream, egg products and solid powder, taste detection, color evaluation, application of stabilizer / emulsifier and development of new products.

The UHT integrates heating, disinfection, cooling and heat recovery, reflecting real production data. Therefore, small-scale production by universities, research institutes and manufacturing units is an ideal choice.

Barreled sterile bag filling machine

Function:

The aseptic packaging of concentrated ketchup and other liquids can be stored at room temperature for more than one year, which can save the cost and risk of low-temperature refrigerated transportation

features:

▼ the product is equipped with a control system composed of man-machine interface and PLC, and the operation is simple and clear.

▼ in addition, it also has automatic inspection and protection functions.

▼ protection function: the electromagnetic flowmeter system improves the filling accuracy and achieves quantitative filling

Automatic bag packing machine

Function:

Paste filling machine is an automatic precision equipment, which can seal and package other cold and hot sauces, such as ketchup.

features:

▼ packaging speed: 30-60 bags / min;

▼ bag size l50-180mm, width 50-120mm

▼ control system PLC + screen;

▼ measuring cup with small weighing error;

▼ roll up the bag to make the package smoother;

▼ material: stainless steel;

Automatic tomato paste can sealing machine

Function:

It is suitable for round can seams of various sizes such as tinplate, aluminum, pet or other plastic cans.

features:

▼ this machine is specially designed for automatic sewing of round tanks (diameter 52-105mm).

▼ this is an automatic vacuum sealing machine. It is mainly used for vacuum, sealing or automatic spray tank sealing

▼ the machine has high cutting precision and high efficiency. It is simple and convenient to adjust the tool.

▼ high alloy steel is used for six fork flap, seam chuck and seam roller

Automatic cleaning CIP system of ketchup production line.

It is mainly composed of acid tank, alkali tank, hot water tank and various pipelines. Centrifugal pump is used to transport cleaning fluid, which is forced to circulate in material pipelines and equipment to achieve the purpose of cleaning. Therefore, there is no need to disassemble the pipeline equipment, which can improve the utilization rate of the equipment and reduce the labor intensity of workers.

After our factory manufactures the ketchup production line, we will exchange the transportation details of machinery and equipment with customers to ensure that customers receive the machinery and equipment they need in the shortest time. After customers receive the ketchup production line, we will help customers carry out installation and commissioning, so as to ensure that the ketchup production line can be used normally in customers' factory, The problems encountered by customers in using the ketchup production line can get the professional help of after-sales engineers, so that the customer's factory can meet the design requirements of the project. In the later stage, the demand for improving the production line capacity can also be quickly met. We will provide customers with all the accessories required by the ketchup production line and solve all the problems encountered in the production process of the ketchup production line, The two sides will establish a good long-term cooperative relationship.