With the improvement of people's living standards, there are many pasteurized milk in the daily food list. These pasteurized milk come from the same place, which is the milk production line. In the milk production line, how do our machines and equipment pasteurize the milk? How do these pasteurizers operate in the production line? The following article will give you a lot of knowledge in this field.

Bacteria were discovered in the mid-19th century. Scientists and doctors realize that bacteria are the cause of most diseases and, obviously, death. Therefore, it is logical to kill these malicious bacteria in everything that human beings must deal with. At the end of the 19th century, pasteurization became not only a desirable behavior, but also a vital behavior. This process enables milk to safely kill all bacteria. Since pasteurized milk became something we used to. Another view is that pasteurization can not only kill bacteria, but also kill most nutrients, which makes milk almost useless to the human body. But let's remember that the benefits of eating raw milk are controversial because adults can't really get all the nutrients from this drink.

Almost every milk production line is equipped with different types of sterilizers, and the pasteurization process is basically boiling. Substances requiring pasteurization must reach a certain temperature at which all microorganisms will die. Therefore, pasteurized milk is raw milk that is heated to the boiling point and then cooled rapidly. After this process, milk drinks not only become safe, but also can be stored for a longer time.

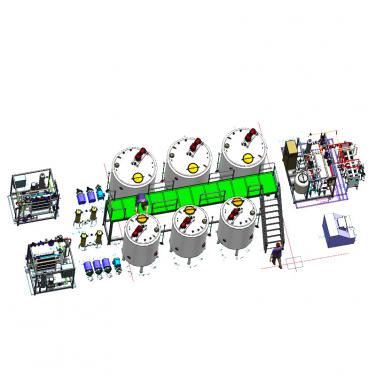

Pasteurizer in milk production line can be used for pet hot filling or roof filling sterilization. Our pasteurizer is divided into two types in terms of control mode, one is full-automatic control and the other is semi-automatic control.

Full automatic control: UK Spirax sarco steam pressure reducing valve, German Burkert or Spirax sarco temperature control system, German labom temperature sensor, Anthony paperless temperature recorder, south hot water pump, Siemens PLC full automatic control, with touch screen, temperature control accuracy ± 0.5 degrees.

Semi automatic control: British Spirax sarco steam pressure reducing valve, German Burkert or Spirax sarco temperature control system, German labom temperature sensor, Anthony paperless temperature recorder, south hot water pump and Siemens logo control. The temperature control accuracy is ± 0.5 degrees.

A. Plate heat exchanger;

B. Material balance drum;

C. Hot water balance bucket;

D. Hot water filling pump;

E. Material transfer pump;

F. Water heater;

G. Electric box;

H. Stainless steel valves and pipes, etc.