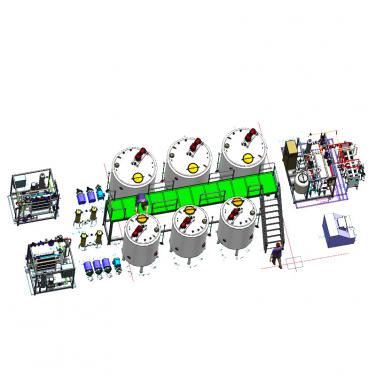

Flavor jelly processing line Flavor jelly making machines

Jun 1, 2022

BEYOND provides a customized flavor jelly processing line, and neutral products are sterilized by on-line high-temperature UHT; Aseptic canning can replace the traditional hot filling production, and can be stored and transported at normal temperature; At the same time, the problem that the product is easy to change color and taste due to long-term high temperature and affects the flavor is avoided. Pass through water bath cooling device is adopted for acid products. The device adopts circulating cold water and conveying device, which speeds up the cooling speed and improves the production efficiency.

In the whole process of material transportation, the insulation pipeline with insulation device is used to avoid the influence of various factors on the materials, which not only improves the work efficiency, but also ensures the product flavor.

We can design and manufacture the flavor jelly processing production line according to the actual needs of customers, and the after-sales engineer assists customers in the installation and commissioning of the flavor jelly processing production line, so as to ensure that customers' investment gets rich returns. Our customers are all over different countries and industries, and they have achieved great success in their respective fields.

In the whole process of material transportation, the insulation pipeline with insulation device is used to avoid the influence of various factors on the materials, which not only improves the work efficiency, but also ensures the product flavor.

We can design and manufacture the flavor jelly processing production line according to the actual needs of customers, and the after-sales engineer assists customers in the installation and commissioning of the flavor jelly processing production line, so as to ensure that customers' investment gets rich returns. Our customers are all over different countries and industries, and they have achieved great success in their respective fields.

Прошлая страница:

Coconut processing production line

Следующая страница:

Coconut milk processing line Coconut milk making equipment

Новости

Популярная продукция